The team at Finca Monteblanco, led by producer Rodrigo Sanchez in La Tocora de San Adolfo, Huila, Colombia has a savvy system for harvesting and processing coffees. Climate change has turned Colombia’s once concentrated harvest into a nearly year long affair, with cherries on the same tree ripening at different times and the harvest across the farm coming over the course of many months.

To make the most of the full harvest, the folks at Monteblanco measure the degrees Brix of each lot of cherries as they come off the trees to determine the sugar content. Based on the amount of sugar in the coffee cherries, Monteblanco uses a protocol — established through years of testing, trial, and error — to designate the appropriate processing for each lot. Freshly harvested cherries in the early stages of Natural processing.

Freshly harvested cherries in the early stages of Natural processing.

20–23 degrees Brix — Natural

Natural processing leaves the coffee beans inside the cherries to dry, a process that can take well over a month in the cool, cloud-covered mountains of Huila. During this time, cherries are at risk of spoilage or of over-fermenting, a defect that leads to flavors of cooked or rotten fruit in the cup. In the best case, Natural processed coffees are known for their sweetness and juiciness, but in the worst case they are associated with inconsistency within a lot or instability over even a short storage period.

By choosing cherries with a lower level of sugar to begin with, those existing sugars have time to be fully absorbed into the bean without risking the defects Natural processing can cause if the drying cherries come into contact with excess rain or mist. Producers Rodrigo Sanchez and Claudia Samboni

Producers Rodrigo Sanchez and Claudia Samboni

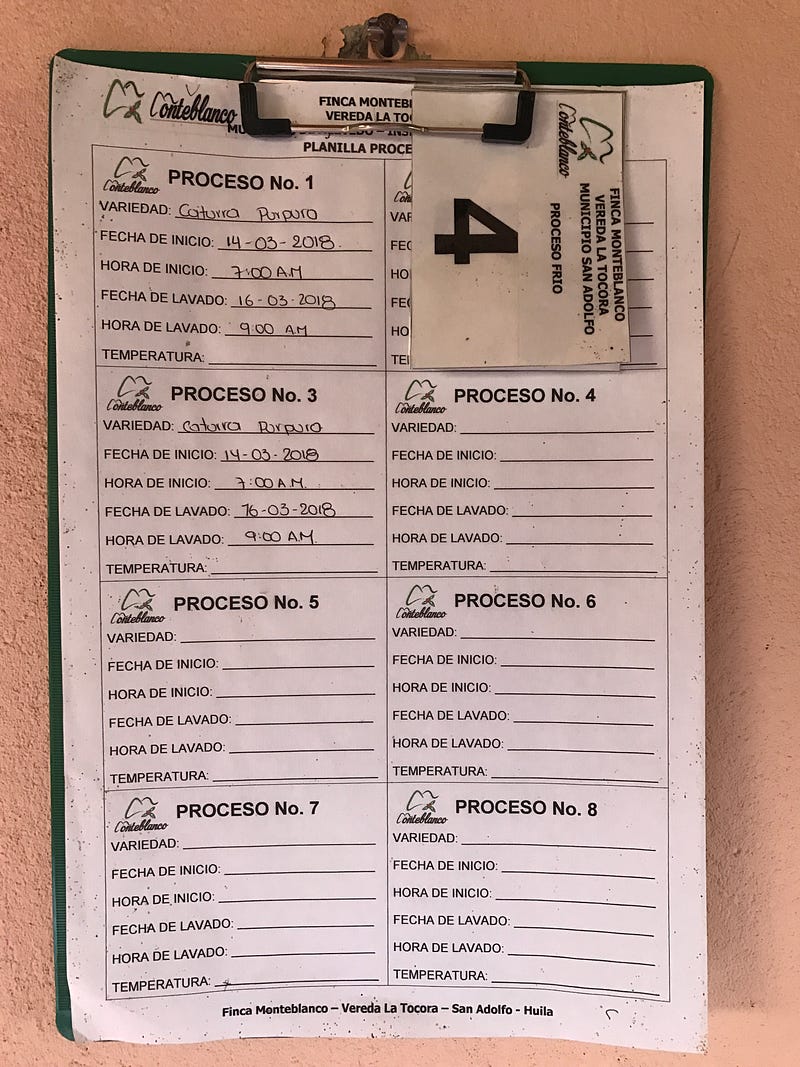

The farm’s 18 hectares, measuring temperature during double fermentation.

The farm’s 18 hectares, measuring temperature during double fermentation.

22 degrees Brix — Double Fermentation

Cherries ferment for 36 hours in a tank and are then depulped and left to ferment an additional 44 hours before being washed and transferred to shaded beds to dry for 28 days. Double Fermentation increases the time the bean is in contact with the sugars from the cherry, ideal for coffees with a slightly higher Brix content than those destined for Natural processing.

The goal of Double Fermentation is to bring out the sweetness and complexity of the coffee. As long as the cherries do not exceed 23 degrees Brix to begin with, the first fermentation phase of the Double Fermentation process can increase Brix readings by as much as 4 degrees Brix, provided that the pH does not drop below 5 and disrupt the equilibrium between body and acidity. Producers from Brazil try out Brix measurement on Monteblanco

Producers from Brazil try out Brix measurement on Monteblanco

24–26 degrees Brix — Cold Fermentation Natural

After harvest, floater cherries are removed and the remaining defect-free cherries are packed in GrainPro bags and placed in a refrigerator with a temperature between 12–15° C for 52 hours. Placing cherries in a refrigerator slows the fermentation process so that the bean has time to absorb the cherries’ sugars, without risking the over fermentation that can occur rapidly at higher temperatures.

After they are removed from the refrigerator, cherries rest for 8 hours to reach ambient temperature. Cherries are then taken directly to solar drying beds where they dry three days, after which they are transferred to shaded beds to dry for the remaining 30–37 days. This method optimizes the higher sugar content while using lower temperatures to prevent the occurrence of defects commonly associated with Natural processing.

24–27 degrees Brix — Washed

Fully washing coffee is the traditional process for all of Colombia. As a nation of coffee producers, Colombia made a name for itself with its “smooth milds” and worked for over a century to establish itself as a provider of clean, consistent, delicious fully washed coffees. Regulatory agencies in Colombia, through the Colombian Federation of Coffee Growers producers’ guild, made sure that all coffees exported under the mark Café de Colombia adhered to tiers of quality standards. It is much easier to sort out defects in Washed coffee, and the milling and purchasing infrastructure, both cooperative and private, is designed to commercialize coffee in parchment.

Washing coffee remains a popular choice among producers. While Natural processing uses less water and less electricity than washing coffee, it requires much more drying bed space and labor power to constantly turn the cherries, which sometimes take twice as long as washed coffee to dry. On Monteblanco, washed lots tend to be larger than those of other processes because Washed processing remains the most efficient of the methods available. Coffees in the range of 24–27 degrees Brix have sufficient sugar levels already that the beans will retain this sweetness through processing and roasting.

Washed coffee is harvested, depulpled, left to naturally ferment for the mucilage to loosen from the bean, and then fully washed and moved to solar and shaded beds to dry.

Tanks, charts, and refrigerator for Cold Processing (2018).

Tanks, charts, and refrigerator for Cold Processing (2018).

28 degrees Brix — Cold Fermentation Washed

Cold Fermentation Washed is essentially a decelerated Washed processing, one where the beans are depulped from their cherries but left to rest in a refrigerator, rather than at ambient temperature, for the fermentation stage.

Rodrigo and his team pioneered this process in 2015, taking cues from the wine industry, where temperature control during fermentation is the norm. The refrigerator for Cold Fermentation is kept between 10–13° C and beans ferment inside for 76 hours. Cherries with 28 degrees Brix might have resulted in defects in normal Washed processing, but this slower process preserves the sweetness available from the extra sugars without risking spoilage from over fermentation.

Natural and washed coffees drying side by side.

Natural and washed coffees drying side by side.

By using an array of processing options, Finca Monteblanco produces clean and consistent microlots with enviable sweetness, floral notes, and complex fruit flavors while also creating clean and consistent larger lots of more traditional profiles. Rodrigo and his team on the farm and in the mill have developed this processing protocol over many years as a way to respond to changes in harvest patterns as well as changes in roaster and consumer tastes. Their flexibility and agility in pioneering new processing styles makes us proud to call them our partners in moving coffee forward! Shaded drying beds.

Shaded drying beds.